The inception of OnePass, including its ERP Systems for Manufacturing, was a response to the challenges that often bog down HR departments. Fueled by a shared vision, a group of dedicated professionals embarked on a mission to transform HR management. We envisioned a comprehensive solution that would seamlessly integrate all aspects of HR, from recruitment to performance evaluation, under one roof.

Amidst the journey, we encountered obstacles that only strengthened our resolve. Countless hours were invested in envisioning the optimal user experience, designing an intuitive interface, and refining features to simplify intricate HR tasks. Contact us for more requirements and join us onboard starting today!

Streamlining Core Processes

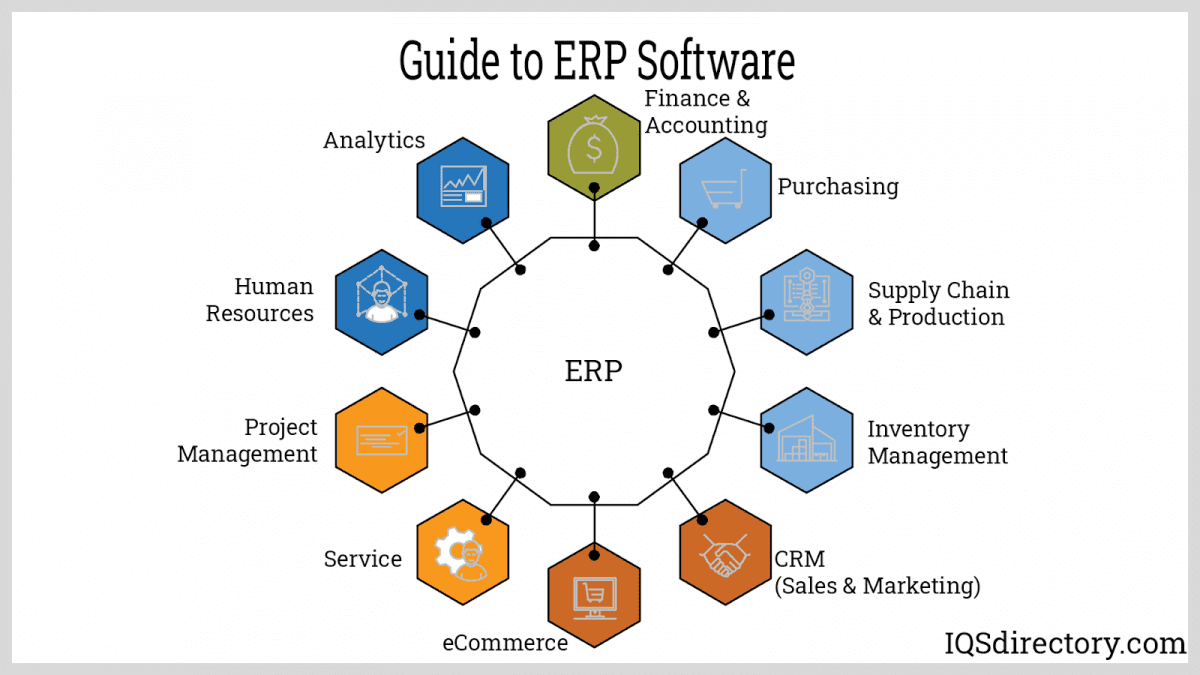

In the competitive world of manufacturing, companies need effective tools to reduce costs and boost profitability. An Enterprise Resource Planning (ERP) system is one of the best solutions. ERP systems integrate various functions within a manufacturing organization, providing a comprehensive platform that streamlines operations and enhances efficiency.

Improving Resource Management

Implementing an ERP system in manufacturing starts with integrating core processes like production planning, inventory management, and procurement. This integration ensures all departments work together, eliminating silos and fostering collaboration. With a unified platform, manufacturers can better manage resources, reduce waste, and optimize production schedules.

Leveraging Real-Time Data

ERP systems offer the advantage of providing real-time data and analytics. This capability allows manufacturers to make informed decisions quickly, adjust production processes, and allocate resources efficiently. With accurate and timely information, companies can identify bottlenecks, forecast demand, and improve inventory management, leading to significant cost savings.

Enhancing Supplier and Customer Relationships

Moreover, ERP systems facilitate better supplier and customer relationship management. By automating procurement processes and tracking supplier performance, manufacturers can negotiate better terms and reduce costs. Enhanced visibility into customer orders and preferences enables manufacturers to improve service levels, increasing customer satisfaction and loyalty.

Ensuring Compliance and Managing Risks

ERP systems also play a crucial role in compliance and risk management. In a regulated industry like manufacturing, adhering to standards and regulations is essential. ERP systems help ensure compliance by providing traceability and documentation capabilities, reducing the risk of non-compliance and associated penalties.

Conclusion

In conclusion, ERP systems for manufacturing are vital for reducing costs and increasing profitability. By integrating core processes, providing real-time data, improving supplier and customer relationships, and ensuring compliance, ERP systems empower manufacturers to operate more efficiently and competitively. Investing in an ERP system is a strategic move that leads to long-term success and sustainability in the manufacturing industry.